PRE-STRESSED CONCRETE REINFORCEMENT

Pre-tensioning tendon

CFCCs used as pre-tensioning tendon are 7 strands or uni-strand cables.

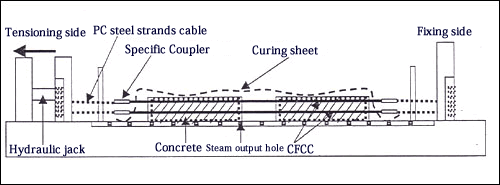

CFCC can be stressed as same as ordinal PC steel strands cable by means of connecting a PC strands cable of about the same diameter of CFCC and CFCC cut into the desired length through a specific coupler.

(Refer to the drawing and the girder manufacsturing procedure shown below.)

CFCC can be stressed as same as ordinal PC steel strands cable by means of connecting a PC strands cable of about the same diameter of CFCC and CFCC cut into the desired length through a specific coupler.

(Refer to the drawing and the girder manufacsturing procedure shown below.)

| Manufacturing procedure of the girder |

| 1.Installing CFCC, and coupling with PC steel strands cable |

| 2.Pre-loading and final loading of CFCC |

| 3.Distribution and binding of stirrups |

| 4.Placing formwork, pouring concrete and curing |

| 5.Displacement of formwork and transfer of stress to the concrete girder |

In regard to design and installation of pre-stressed concrete using CFCC, please refer to "Recommendation for Design and Construction of Concrete Structures using Continuous Fiber Reinforcing Materials" issued by Japan Society of Civil Engineers (JSCE)

Post-tensioning tendon

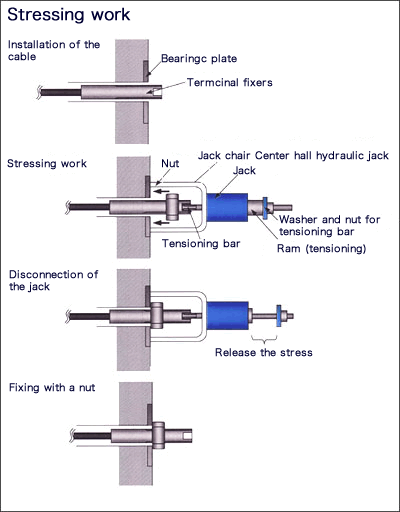

CFCC is cut into the designated length and terminal fixers are attached on the both ends at the CFCC plant in Japan. CFCC post-tensioning tendons are shipped after the fabrication and delivered to each job site.

CFCC post-tensioning tendons are stressed with a center-hall hydraulic jack, a jack chair, and a tension bar, etc. (Refer to the drawing shown below.)

In regard to design and installation of pre-stressed concrete using CFCC, please refer to "Recommendation for Design and Construction of Concrete Structures using Continuous Fiber Reinforcing Materials" issued by Japan Society of Civil Engineers (JSCE)