APPLICATIONS

4 major advantages of ACFR

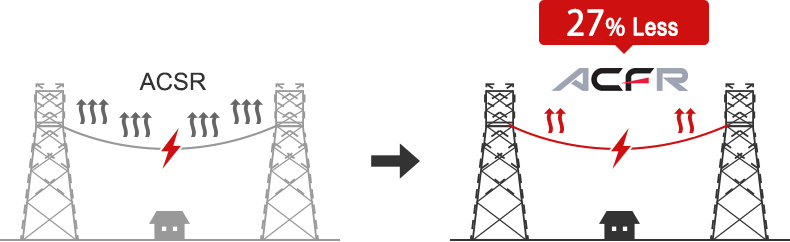

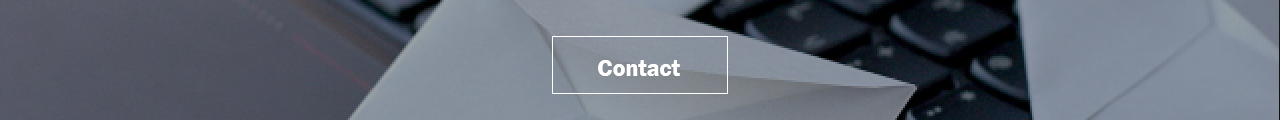

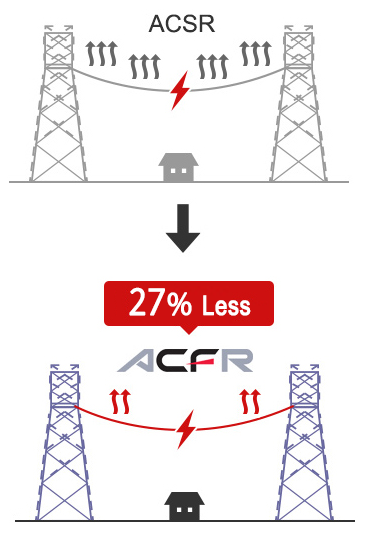

Low Loss

ACFR can reduce transmission loss with the following three advantages compared to conventional conductors

27% less under certain design and operation conditions

- Larger Aluminum Cross-Sectional Area

- Non Core Loss

- Annealed Aluminum

Reconductor with

Low loss without tower modification

New Line with

Low loss with larger conductor design

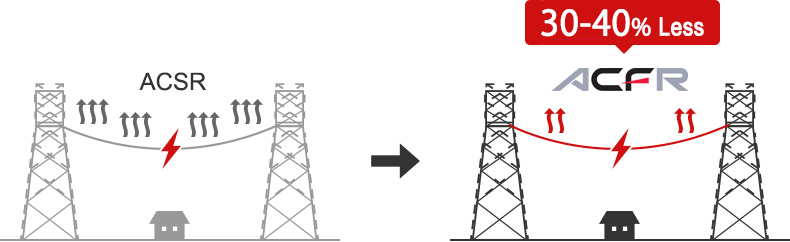

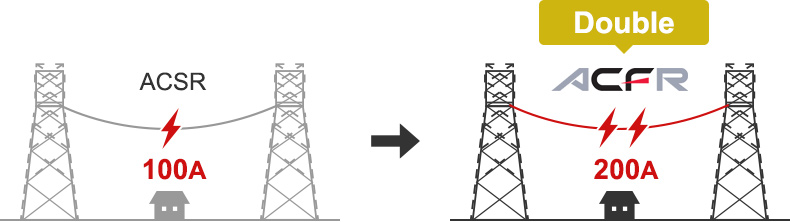

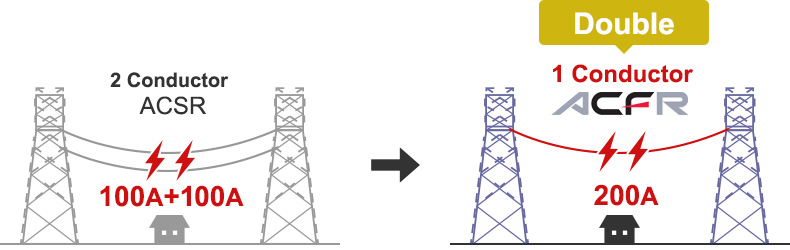

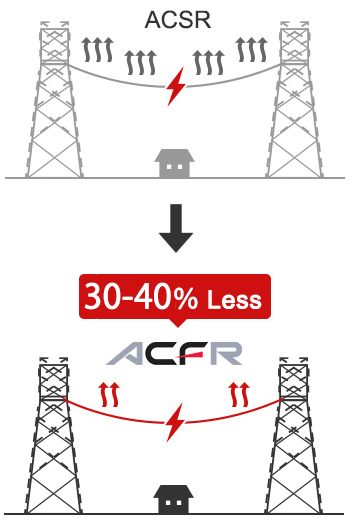

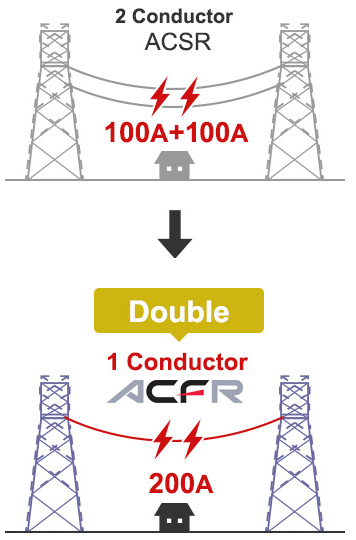

High Capacity

ACFR can increase transmission capacity with the following three advantages compared to conventional conductors

More than double under certain design and operation conditions

- Larger Aluminum Cross-Sectional Area

- CFCC core's durability with high temperature

- Annealed Aluminum

Reconductor with

Increase capacity without tower modification

New Line with

Decrease the number of conductors and the tower's structural cost

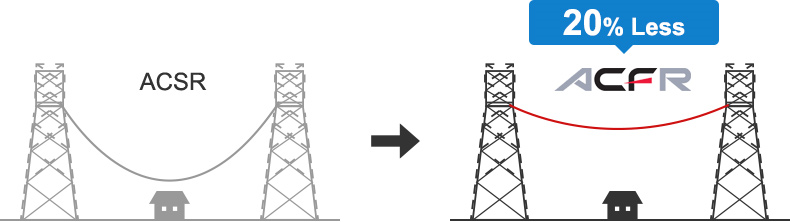

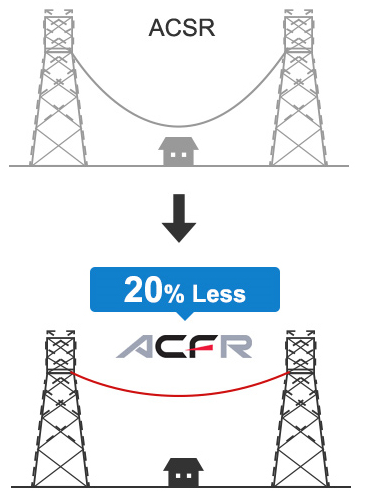

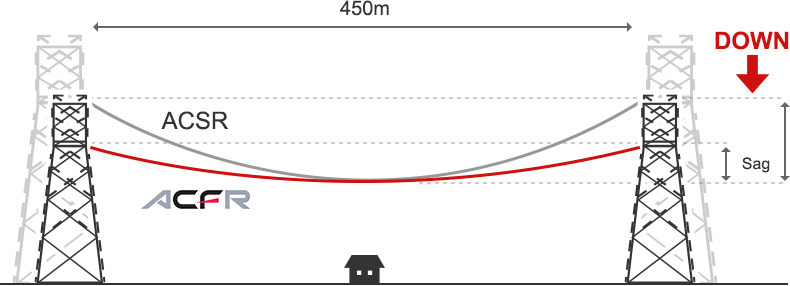

Low Sag

ACFR is a superior low sag conductor with the following advantages

20% less sag under certain design and operation conditions

- Light Weight

- High Modulus

- Low Liner Expansion

Reconductor with

Sag improvement without tower modification

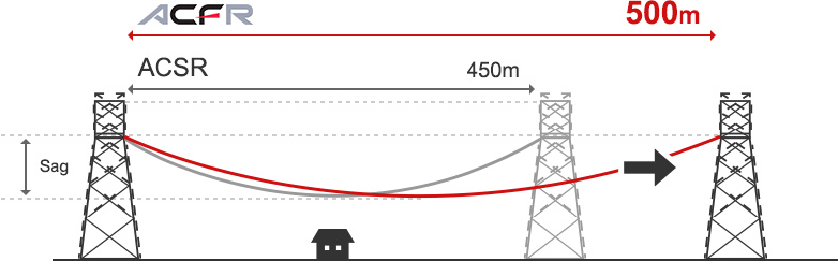

New Line with

Lower tower height thanks to superior sag performance, which leads to a reduction in the tower construction cost lead time

Longer span thanks to superior sag performance, which leads to a reduction in the construction cost by cutting the number of towers and the lead time

Low Sag - Low Loss and Low Sag - High Capacity design is available.

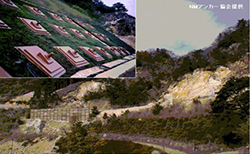

Special Applications

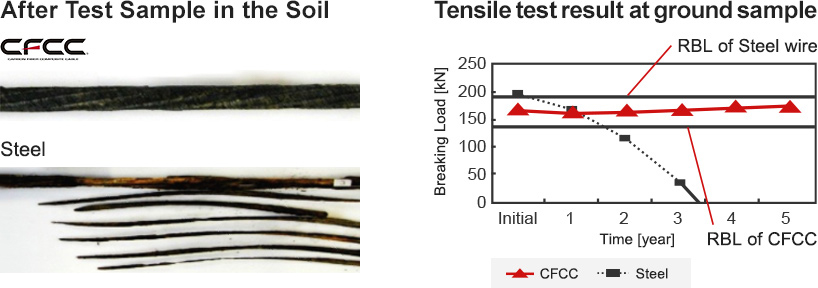

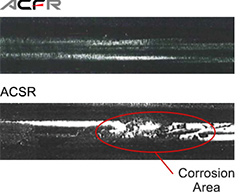

Anti Corrosion

CFCC core has high corrosion resistance, and better material life is expected compared to conversional steel core conductor.

River Crossings

Major advantage in terms of construction cost and shorter lead time for special long span projects such as river crossings thanks to superior sag performance

About Salt Spray Test

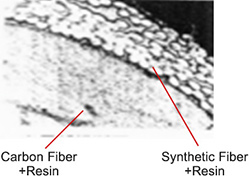

Blow up Surface

Carbon fiber and aluminum have no electrical contact

- Core is covered with synthetic fiber and resin

- Synthetic fiber and resin are insulation

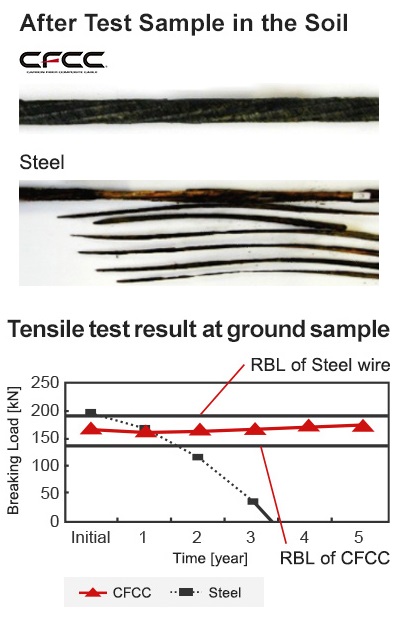

ACFR's core, CFCC®, has high acid resistance capability

Test conditions

- Test: CFCC, steel wire

- Burial depth: Surface, 10 -14 m

- Acid hot spring gushes out near test piece

- Acidity pH : 2.25 (hot spring); 2.4 (soil)

- H2S content at hot spring: 6.05 ppm

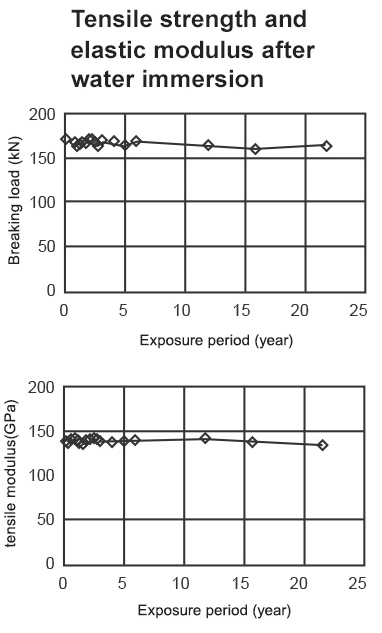

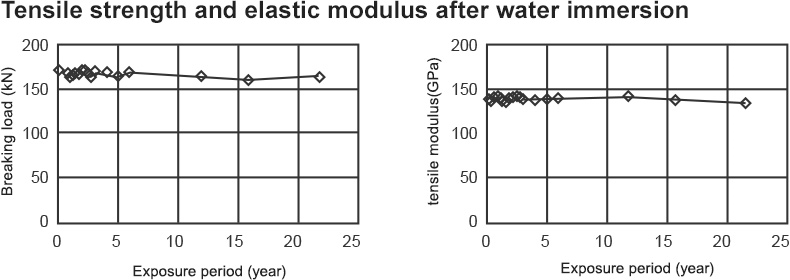

ACFR's core, CFCC®, has high water resistance capability

Water-submersion test

No deterioration in tensile strength

- CFCCs are immersed in fresh water for several years

- Tensile tests are undertaken using immersed CFCC