General Information of CFCC

Outline of CFCC

Notes on handling CFCC:

CFCC is a composite material consisting of carbon fibers and a matrix resin. As CFCC is different from steel members, special care should be taken; i.e. not to cause flaws, deformation or deterioration on handling. Especially, refrain from dropping hard and heavy objects (such as hammers) / sparking of welding/fire on CFCC, or bending CFCC steeply. CFCC damaged by any of these should be discarded.

| (Cross section figure) | Designation | Diameter (mm) |

Effective cross-sectional area (mm2) |

Guaranteed breaking load (kN) |

Unit weight per meter (g/m) |

Elastic modulus (kN/mm2) |

| Uni-strand |

U 5.0Φ | 5.0 | 15.9 | 40.4 | 30 | 165 |

| 7 strands |

1×7 7.9Φ | 7.9 | 31.1 | 79.3 | 60 | 150 |

| 1×7 10.8Φ | 10.8 | 57.8 | 147.2 | 112 | 150 | |

| 1×7 12.5Φ | 12.5 | 75.6 | 192.5 | 146 | 150 | |

| 1×7 15.2Φ | 15.2 | 115.6 | 294.4 | 223 | 150 | |

| 1×7 17.2Φ | 17.2 | 151.1 | 385.0 | 292 | 150 | |

| 1×7 19.3Φ | 19.3 | 186.7 | 475.6 | 360 | 150 | |

| 1×7 26.2Φ | 26.2 | 339.2 | 864.1 | 655 | 150 | |

| 1×7 28.9Φ | 28.9 | 412.5 | 1,051 | 796 | 150 | |

| 19 strands |

1×19 34.3Φ | 34.3 | 567.0 | 1,342 | 1,095 | 145 |

| 37 strands |

1×37 40.9Φ | 40.9 | 798.7 | 1,765 | 1,544 | 145 |

| (Cross section figure) |

Uni-strand |

| Designation | U 5.0Φ |

| Diameter (mm) | 5.0 |

| Effective cross-sectional area(mm2) | 15.9 |

| Guaranteed breaking load(kN) | 40.4 |

| Unit weight per meter(g/m) | 30 |

| Elastic modulus(kN/mm2) | 165 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 7.9Φ |

| Diameter (mm) | 7.9 |

| Effective cross-sectional area(mm2) | 31.1 |

| Guaranteed breaking load(kN) | 79.3 |

| Unit weight per meter(g/m) | 60 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 10.8Φ |

| Diameter (mm) | 10.8 |

| Effective cross-sectional area(mm2) | 57.8 |

| Guaranteed breaking load(kN) | 147.2 |

| Unit weight per meter(g/m) | 112 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 12.5Φ |

| Diameter (mm) | 12.5 |

| Effective cross-sectional area(mm2) | 75.6 |

| Guaranteed breaking load(kN) | 192.5 |

| Unit weight per meter(g/m) | 146 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 15.2Φ |

| Diameter (mm) | 15.2 |

| Effective cross-sectional area(mm2) | 115.6 |

| Guaranteed breaking load(kN) | 294.4 |

| Unit weight per meter(g/m) | 223 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 17.2Φ |

| Diameter (mm) | 17.2 |

| Effective cross-sectional area(mm2) | 151.1 |

| Guaranteed breaking load(kN) | 385.0 |

| Unit weight per meter(g/m) | 292 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 19.3Φ |

| Diameter (mm) | 19.3 |

| Effective cross-sectional area(mm2) | 186.7 |

| Guaranteed breaking load(kN) | 475.6 |

| Unit weight per meter(g/m) | 360 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×19 26.2Φ |

| Diameter (mm) | 26.2 |

| Effective cross-sectional area(mm2) | 339.2 |

| Guaranteed breaking load(kN) | 864.1 |

| Unit weight per meter(g/m) | 655 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×19 28.9Φ |

| Diameter (mm) | 28.9 |

| Effective cross-sectional area(mm2) | 412.5 |

| Guaranteed breaking load(kN) | 1,051.0 |

| Unit weight per meter(g/m) | 796 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

19 strands |

| Designation | 1×19 34.3Φ |

| Diameter (mm) | 34.3 |

| Effective cross-sectional area(mm2) | 567.0 |

| Guaranteed breaking load(kN) | 1,342.0 |

| Unit weight per meter(g/m) | 1,095 |

| Elastic modulus(kN/mm2) | 145 |

| (Cross section figure) |

37 strands |

| Designation | 1×37 40.9Φ |

| Diameter (mm) | 40.9 |

| Effective cross-sectional area(mm2) | 798.7 |

| Guaranteed breaking load(kN) | 1,765.0 |

| Unit weight per meter(g/m) | 1,544 |

| Elastic modulus(kN/mm2) | 145 |

| (Cross section figure) | Designation | Diameter (mm) |

Effective cross-sectional area (mm2) |

Guaranteed breaking load (kN) |

Unit weight per meter (g/m) |

Elastic modulus (kN/mm2) |

| Uni-strand |

U 5.3Φ | 5.3 | 17.9 | 31.7 | 34 | 160 |

| U 7.2Φ | 7.2 | 32.7 | 58.1 | 62 | 160 | |

| U 9.7Φ | 9.7 | 59.5 | 105.6 | 112 | 160 | |

| 7 strands |

1×7 13.0Φ | 13.0 | 83.3 | 147.8 | 159 | 150 |

| 1×7 15.9Φ | 15.9 | 125.0 | 221.7 | 238 | 150 | |

| 1×7 18.4Φ | 18.4 | 166.7 | 295.6 | 317 | 150 | |

| 1×7 19.5Φ | 19.5 | 187.5 | 332.6 | 357 | 150 | |

| 1×7 26.8Φ | 26.8 | 354.2 | 628.2 | 675 | 150 | |

| 1×7 29.1Φ | 29.1 | 416.7 | 739.1 | 794 | 150 |

| (Cross section figure) |

Uni-strand |

| Designation | U 5.3Φ |

| Diameter (mm) | 5.3 |

| Effective cross-sectional area(mm2) | 17.9 |

| Guaranteed breaking load(kN) | 31.7 |

| Unit weight per meter(g/m) | 34 |

| Elastic modulus(kN/mm2) | 160 |

| (Cross section figure) |

Uni-strand |

| Designation | 1×7 7.2Φ |

| Diameter (mm) | 7.2 |

| Effective cross-sectional area(mm2) | 32.7 |

| Guaranteed breaking load(kN) | 58.1 |

| Unit weight per meter(g/m) | 62 |

| Elastic modulus(kN/mm2) | 160 |

| (Cross section figure) |

Uni-strand |

| Designation | 1×7 9.7Φ |

| Diameter (mm) | 9.7 |

| Effective cross-sectional area(mm2) | 59.5 |

| Guaranteed breaking load(kN) | 105.6 |

| Unit weight per meter(g/m) | 112 |

| Elastic modulus(kN/mm2) | 160 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 13.0Φ |

| Diameter (mm) | 13.0 |

| Effective cross-sectional area(mm2) | 83.3 |

| Guaranteed breaking load(kN) | 147.8 |

| Unit weight per meter(g/m) | 159 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 15.9Φ |

| Diameter (mm) | 15.9 |

| Effective cross-sectional area(mm2) | 125.0 |

| Guaranteed breaking load(kN) | 221.7 |

| Unit weight per meter(g/m) | 238 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 18.4Φ |

| Diameter (mm) | 18.4 |

| Effective cross-sectional area(mm2) | 166.7 |

| Guaranteed breaking load(kN) | 295.6 |

| Unit weight per meter(g/m) | 317 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×7 19.5Φ |

| Diameter (mm) | 19.5 |

| Effective cross-sectional area(mm2) | 187.5 |

| Guaranteed breaking load(kN) | 332.6 |

| Unit weight per meter(g/m) | 357 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×19 26.8Φ |

| Diameter (mm) | 26.8 |

| Effective cross-sectional area(mm2) | 354.2 |

| Guaranteed breaking load(kN) | 628.2 |

| Unit weight per meter(g/m) | 675 |

| Elastic modulus(kN/mm2) | 150 |

| (Cross section figure) |

7 strands |

| Designation | 1×19 29.1Φ |

| Diameter (mm) | 29.1 |

| Effective cross-sectional area(mm2) | 416.7 |

| Guaranteed breaking load(kN) | 739.1 |

| Unit weight per meter(g/m) | 794 |

| Elastic modulus(kN/mm2) | 150 |

| CFCC Structures | Structural symbol | Cross-section figure |

| Uni-strand | U | |

| 7 strands | 1x7 | |

| 19 strands | 1x19 | |

| 37 strands | 1x37 |

Terminal fixing methods currently applied for CFCC are roughly distinguished into 3 types shown below:

| Resin filling method | Type | Symbol |

| Expansive material filling method | For single cable (CFCC 1 pc.) | ES |

| For multiple cables (CFCC more than 2 pcs.) | EM | |

| Wedge with buffer material method | For single cable (CFCC 1 pc.) | WS |

1. Assembly of CFCC and terminal fixers is to be done at Tokyo Rope factory.

2. Terminal fixing methods other than above-mentioned are under development to meet diversified usages.

ES

EM

WS

CFCC can be formed into various shapes at our factory.

These parts can be used as reinforcing members for concrete structures.

| Property | Item |

Characteristic value

Character istic value |

|

| General mechanical property | Tensile strength kN/mm2 *1 | CFCC | CFCC-RC |

| 2.55 | 1.77 | ||

| Tensile modulus kN/mm2 *1 | 150 | ||

| Breaking elongation (%) | 1.7 | ||

| Gravity | 1.6 | ||

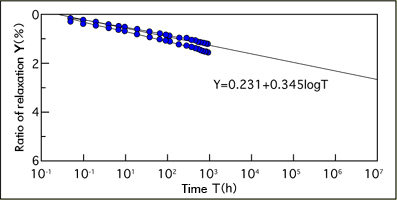

| Static property | Ratio of relaxation (%) *2 | 1.3 | |

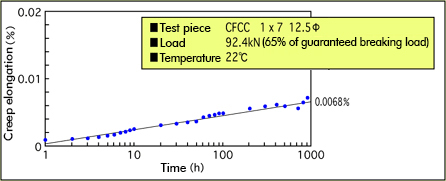

| Creep strain *3 | 0.07x10-3 | ||

| Coefficient of linear expansion (x10-6 /°C) *4 | 0.6 | ||

| Specific resistance (µΩcm) | 3,000 | ||

| Creep failure load ratio *5 | 0.85 | ||

| Miscellaneous | Fatigue capacity (N/mm2) *6 | 780 | |

| Bending stiffness kN·cm2 | 56.9 | ||

| Heat resistance (°C) | 130~180 | ||

| Acid resistance | Superior to steel | ||

| Alkali resistance | Equal to steel | ||

※1. The value was calculated with effective cross-sectional area. (7 strands)

※2. 0.7pu, 1000hrs (20±2°C), in conformity with JSCE-E534

※3. 0.6pu, 1000hrs (20±2°C)

※4. 20°C-200°C, in conformity with JSCE-E536

※5. Creep failure load ratio measured at 1,000,000hrs, according to JSCE-E533 "Test method for creep failure of continuous fibers"

※6. Average stress is 75% of guaranteed breaking load, 2x106 cycles, according to JSCEE-535.

pu:The guaranteed breaking load

Characteristics of CFCC

Characteristics of CFCC - 1

- "CFCC" stands for Carbon Fiber Composite Cable.

- CFCC is a stranded CFRP (Carbon Fiber Reinforced Polymer) which consists of twisted carbon fibers of approx. 7µm dia. and an epoxy resin.

Characteristics of CFCC - 2

| Material | Relative magnetic permeability |

| CFCC | Below 1.000* |

| Non magnetic PC steel (18Mn steel) | 1.003 |

| Iron core | 1,200 |

* Due to the performance of magnetic analysis equipment, values less than 1.000 were immeasurable.

| Material | Coefficient of linear expansion |

| CFCC | 0.6x10-6/°C |

| Steel | 12.0x10-6/°C |

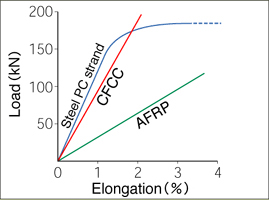

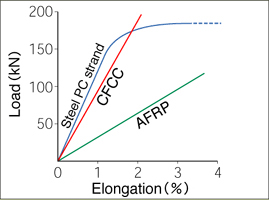

Tensile strength of CFCC is 1.4 - 2.1kN/mm2.

CFCC's tensile elastic modulus of 137kN/mm2 is higher than glass fibers or aramid fibers.

* CFCC 1x7 12.5mm dia.

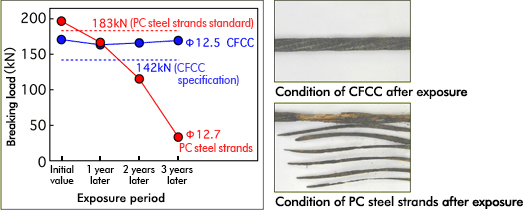

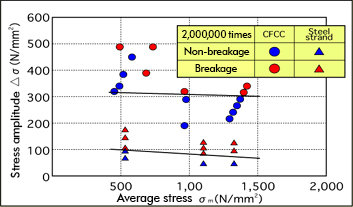

CFCC has higher tensile fatigue resistance in comparison with PC steel strands.

CFCC's relaxation ratio is on the same level as low relaxation PC steel strands.

CFCC's creep elongation is smaller than that of other FRP materials such as glass fibers or aramid fibers, and almost equal to steel cables.