A Light, Durable and Flexible Core

Modernized material science x Sophisticated stranding technology.

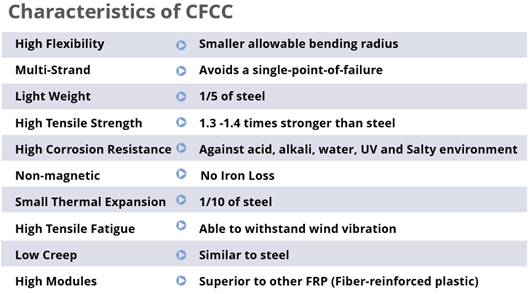

CFCCŌĆśs characteristics far exceed conventional cables, such as high strength, high elasticity, light weight, high corrosion resistance, non-magnetism, and low linear expansion plus practical handling performance and flexibility.

What Is CFCC made of?

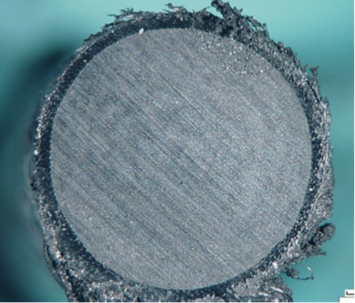

CFCC stands for Carbon Fiber Composite Cable and is produced by forming a compound of carbon fibers (of approx. 7┬Ąm dia.) and thermosetting epoxy resin into a stranded shape. The resins used in CFCC are among the toughest available and can resist operation temp. up to 200┬░ .

- Uni-directional carbon fibers stranded in a themoset epoxy resin matrix.

- Carbon fiber grade is T-700 or higher. Each strand consists of 12,000 filaments.

- Protection layer:overlapping wraps of polyester yarn cover each strand for mechanical and electrical protection

- CFCC has almost no thermal expansion with increased temperature, resulting in much lower sag of ACFR conductors at high temperature operation as compared to standard conductors.

High Grade Carbon Fiber

Carbon Fiber Composite Cable

Aluminum Conductor Fiber Reinforced

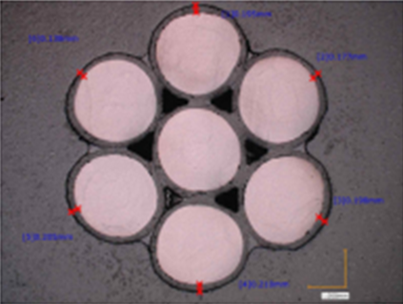

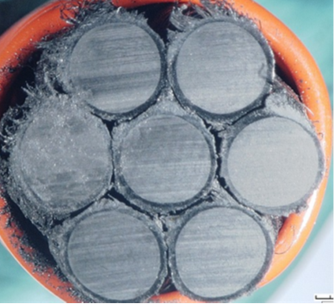

Cross-section of CFCC® by digital microscope

Protection layer: overlapping wraps of polyester yarn (0.05ŃÄ£)

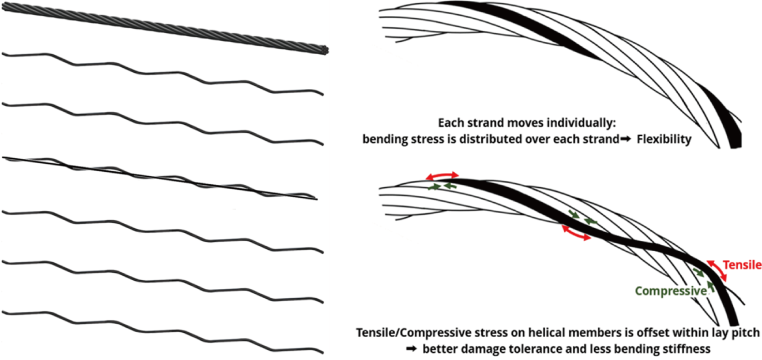

Why is CFCC® stranded?

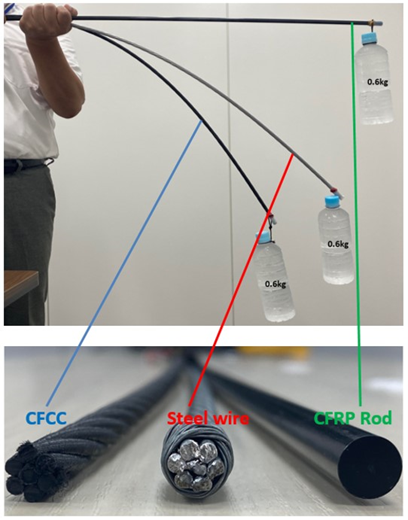

The stranded construction has, due to the interstices, fewer carbon fibers as compared to a same-diameter pultrusion rod.

This results in a slightly lower rated strength, but the important advantages are:

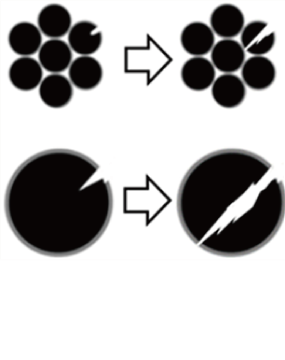

- Structural redundancy: Multi-stranded design avoids single-point-of-failure

- Flexibility: Multi-stranded design allows greater bending before damage

- Less bending stiffness

- Much better damage tolerance

- Practical handling characteristic

- Compatibility with conventional compression type fittings

|

|

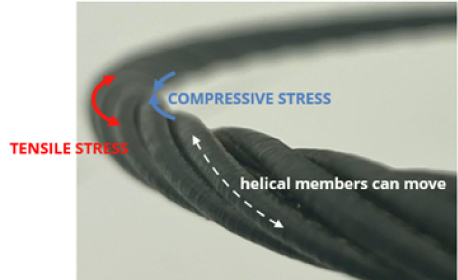

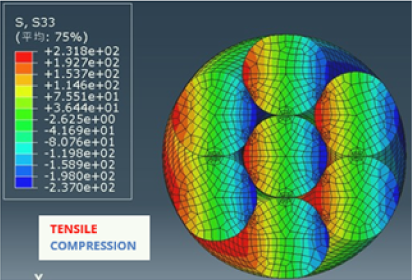

7 free moving strands ŌåÆ Stress distribution ŌåÆ Increased flexibility |

Avoids single-point of failure |

|

|

Figure 1: Close-up of Bent CFCC® |

Figure 2: Stress Distribution on CFCC® |

CHARACTERISTICS OF CFCC®

Lightweight:

About 1/5 weight of steel strands.

Flexible:

Flexible and structurally redundant.

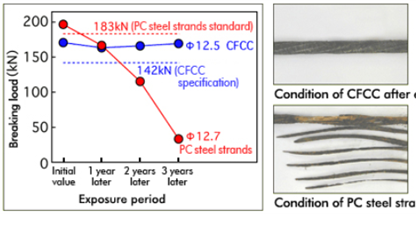

High Corrosion Resistance:

Non-Magnetic /No Iron Loss:

| Material | Relative magnetic permeability |

| CFCC | Below 1.000 |

| Non-magnetic PC steell wire (18Mrs steels) | 1.002 |

| Steel wire | 1,200,000 |

*Values less than 1,000 were immeasureble due to limitation on equipment.

Low Coefficient of Linear Thermal Expansion:

| Material | Coefficient of linear expansion |

|---|---|

| CFCC | 1.0 × 10*/┬░C |

| Steel wire | 11.5 × 10*/┬░C |

High Tensile Strength and Modules of Elasticity:

| Specimen: | Stranded CFCC 1×7-12.5mm dia.(for Civil Eng.) | |

| Tensile strength: | 1.4 - 2.1kN/mm2(Equal or greater than steel.) | |

| Modulus of Elasticity: | 137kN/mm2 |

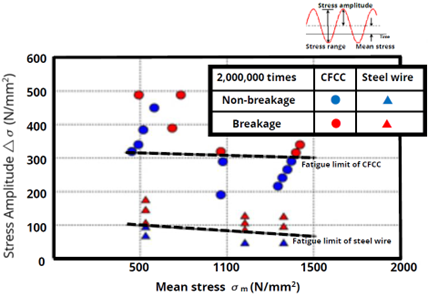

High Tensile Fatigue Resistance:

The graph shown below indicates that CFCC is durable after 2 million stress cycles.

The fatigue limit of CFCC is 300N/mm2 whereas it is 100N/mm2 for steel wire

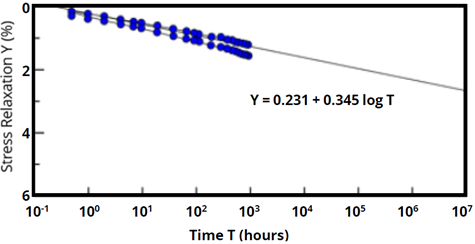

Low Relaxation:

Expected relaxation for initial tension (65% RTS) of CFCC after 10^7 = 10.000,000 hours = 114 years is less than 3%.

Increase in sag of the conductor by relaxation of CFCC core is minimum.

| Specimen: | Stranded CFCC 1×7-12.5mm dia. | |

| Load: | 92.4kN(65% Rated tensile strength) | |

| Temperature: | 22┬░C |

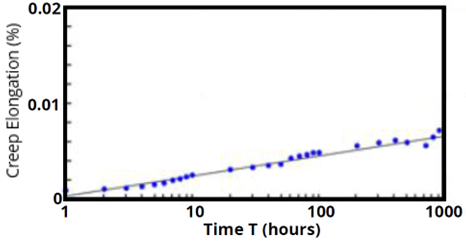

Small Creep Elongation:

| Specimen: | Stranded CFCC 1×7-12.5mm dia. | |

| Load: | 92.4kN(65% Rated tensile strength) |

HISTORY OF CFCC® AND DEVELOPMENT OF ACFR®

CFCC® was initially developed as non-carrasize low-relaxation reinforcing member for civil construction in 1980's

Kitakami CFCC® Production facility

Michigan CFCC® Production facility (USA)

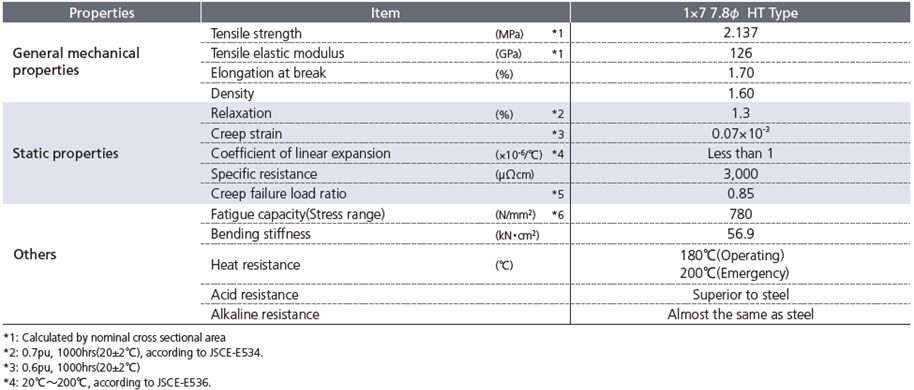

Standard Characteristics & Specification of CFCC®